Application

Application:

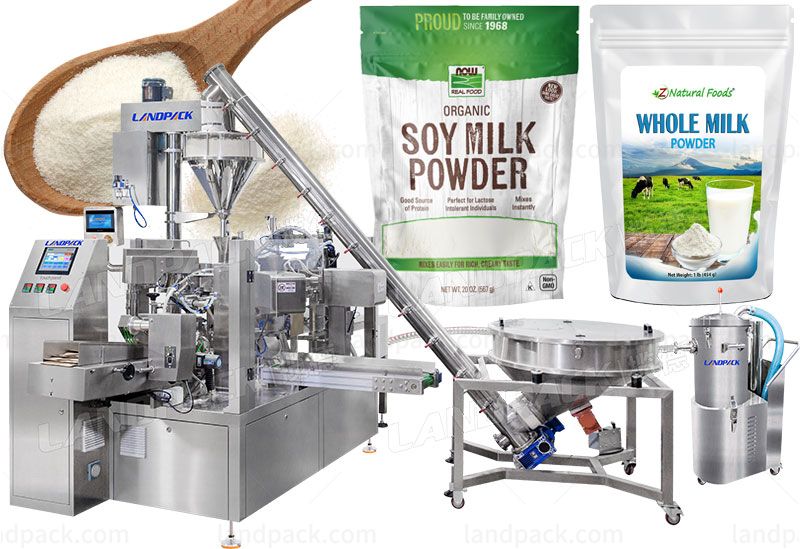

Automatic stand-up zipper pouch packing machine with rotating measuring cup(LDSP-160C/ 210C), It suitable for fully automatic packaging of zipper bags, stand-up bags, 3/4 side-seal bags and other prefabricated bags for various granular products, such as candy, melon seeds, chips, peanuts, nutlet , preserved fruit, jelly, biscuit, confect, camphorball, currant, almond, chocolate, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

Features:

1. The bag feeder is easy to place the bags with pressing-bag accessory.

2. It’s with imported gravity sensor to read whether there is product there .No product , not seal to save bag.

3. With color touch screen for simple operation.

4. The machine adopts Stainless steel 304 appearance, and some accessories are processed with acid and salt-resistant anti-corrosion treatment layer.

5. Majority of accessories will use 304 stainless steel and aluminium oxide ;

6. Optional accessories : inkjet printer, thermal printer, exhaust air, punching and ect.

Specifications:

| Type | LDSP-160 | LDSP-160Y | LDSP-210 | LDSP-260 |

| Bag Type | 3-side, 4 side sealing bag, stand-up bag, handbag, spout bags, zipper bag, compound bag, etc. |

| Bag Size | 110-230mm*80-160mm(L*W) | 70-100mm*110-230(L*W) | 100-210mm/110-320mm(L*W) | 100-260mm/110-320mm(L*W) |

| Filling Range | 10g-100g | 10g-100g | 10g-1kg | 10g-3kg |

| Packing Speed | 20-45bags/min(speed is determined

by the product filling quantity) | 25-50bags/min(speed is determined

by the product filling quantity) | 20-50bags/min (speed is determined

by the product filling quantity) | 20-50bags/min (speed is determined

by the product filling quantity) |

| Machine weight | 800KG | 800KG | 900KG | 1000KG |

| Total Power | 2.0KW | 2.0KW | 2.0KW | 2.0KW |

| Work Flow | 1.Giving bag 2. Pick up the bag(coding) 3.Open the bag up and down 4.Filling

5.Heating sealing 6.Output of product |

|

| Dimensions | 1750mm X 1285mm X 1360mm(L*W*H) | 2140mm X 1366mm X 1360mm(L*W*H) | 2140mm X 1366mm X 1360mm(L*W*H) |

| Collocation | Screw metering,screw elevator |

Optional Devices:

inkjet printer

thermal printer

exhaust air

punching