Features:

1. Easy to operate,adopt advanced PLC from Germany Siemens, mate with touch screen and electric control system, the man-machine interface is friendly.

2. Frequency conversion adjusts the speed: this machine uses frequency conversion equipment, can be adjusted within the range according to the needs of reality in production

3. Automatic checking: no pouch or pouch open error, no fill, no seal. the bag can be used again, avoid wasting packing materials and raw materials.

4. Horizontal conveyer style to giving bag: it can put on more bags on the bag storage and have a low requirement about the quality of bags.

5. It matchs with the glass safty door. The machine will stop working when you open the door. So that it could protect the safty of operators. At the same time, it could prevent dust.

6. Use the plastic bearing, don’t need put on oil, less pollution.

7. Use no oil vacuum pump, avoid polluting the environment in the production.

8. The opening zipper framework is special in the feature of zipper bag,it can avoid distortion or destroy when opne the zipper

9. The packing materials loss low, what this machine is used the preformed bag, the bag pattern is perfect and has a high quality of the sealing part, this improved the product specification

10. Product or packing bag contact parts adopt stainless steel or other materials which accord with the food hygienic requirements, guarantee hygiene and security of the food

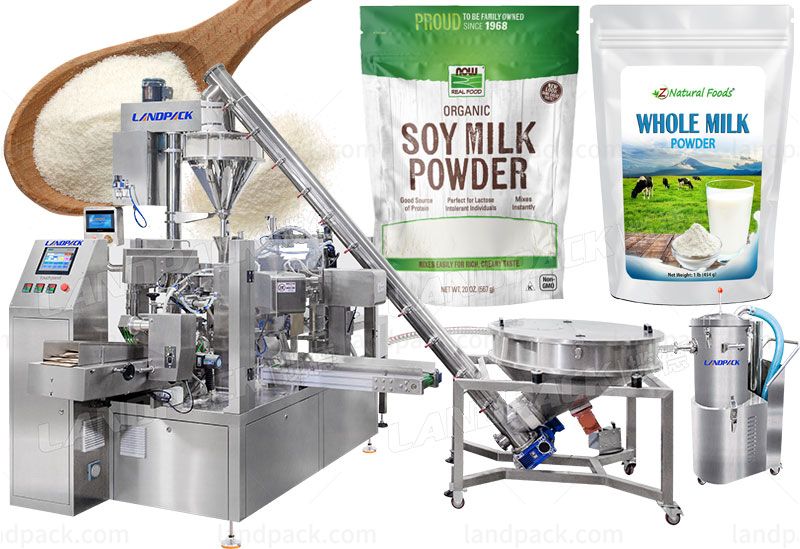

11. With different feeders changed to pack solid, liquid, thick liquid ,powder and so on

12. The packing bag suits in extensive range, suit for multi-layer compound, monolayer PE , PP and so on Preformed bag made by film and paper.