Features:

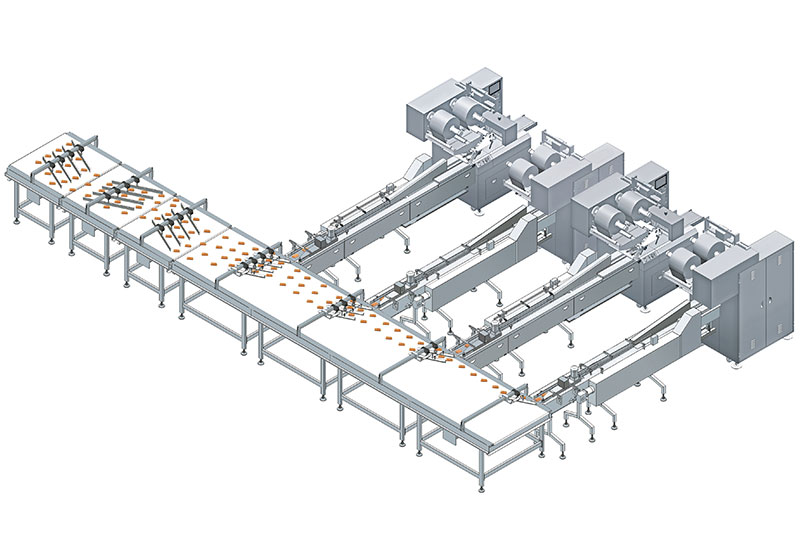

The front conveyor belt of this line can be connected with the outfeed conveyor belt of user's front-end production line for fullautomatic continuous feeding and packing, or by manual products dumping on the conveyor belt for conveying and packing;

The packing line can be customized according to user's individual requirements;

With multi-stage frequency conversion for speed adjustment, servo control and intelligent PLC control system, it is characteristic of simple operation, stable running, high control accuracy and low energy consumption;

Color LCD touch screen with intuitive HMI display for parameters setting. Fault self-diagnostic display on the screen helps trouble shooting;

The data memorystorage function helps to change product sizes;

Automatic defective product rejecting function is available to ensure continuity and stability of production;

High precision and high sensitivity SICK brand photo sensor tracking system ensures accurate product positioning;

The machine configuration is made of complete stainless steel and alu-alloy profiles. With user-friendly design, it is simple and fast in installation, disassembly, repair and maintenance;

At user's demand, extra units of code printer, inkjet printer, air charging device or alcohol spray device can be equipped on the machine for different purpose;