How do Vertical (VFFS) Packaging Machines Work?

A vertical packing machine is a vertical form fill seal(VFFS) packing machine which is widely used in food, chemistry, and some other industries. The vertical packing machine can pack many kinds of granule, powder, and liquid, and they will match the suitable weight, screw metering or measuring pump, and some other devices according to our customer’s requirements. In this article, we are talking about how the packaging machine works from roll film device to packer.

1. Film Transport

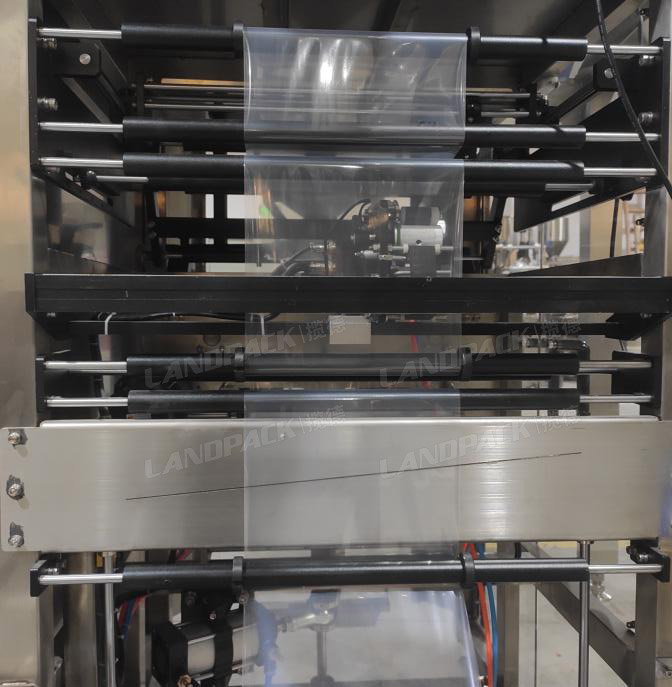

This is the roll film device. Vertical packaging machine uses a single roll of film material to wind on the winding core, which is usually called reel material. The material of the membrane can be various,such as BOPP/ CPP, BOPP/ VMCPP, BOPP/ PE, PET/ VMPET/ PE, PET/ AL/ PE, PET/ PET, Kraft paper/ PE etc. The film roll is placed on the shaft assembly at the rear of the machine. When the vertical packaging machine is running, the film is usually pulled from the roll by a film conveyor belt, which is located on the side of the forming tube at the front of the machine.

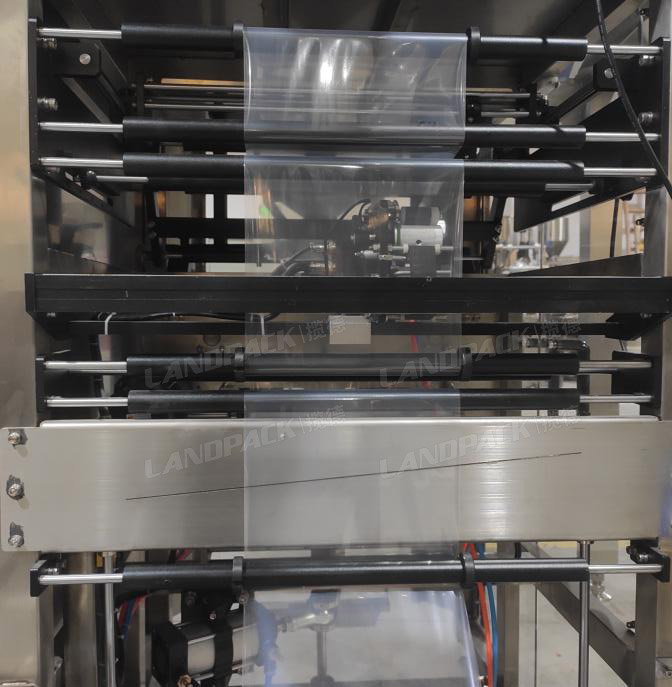

2. Film tension

VFFS packaging machine film unwinds and feeds During the unwinding process. The film is unwound from the roll and passed through a floating arm, which is a weighted pivot arm at the rear of the VFFS packaging machine. The arm contains a series of rollers. When the film is delivered, the arm moves up and down to keep the film under tension. This ensures that the film does not wobble from side to side as it moves.

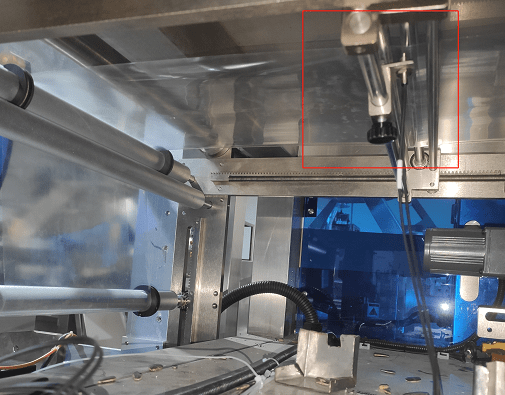

3.Printer(Optional device)

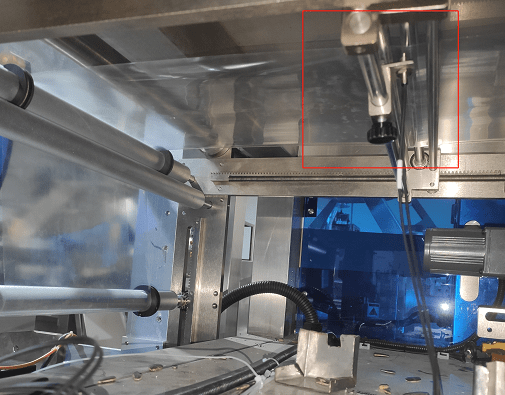

The printer is the optional device that can print production date and expired date. It can be thermal or ink-jet type. When the film comes to this place, it will print information.

4. Film Tracking and Positioning

Once the film passes under the printer, it will be through the electric eye to detect the color mark on the printed film. The electric eye can keep the film correctly positioned so that the film can be cut to the appropriate position. Next, the film passes through the film tracking sensor. When the film passes through the machine, the film tracking sensor detects the position of the film.

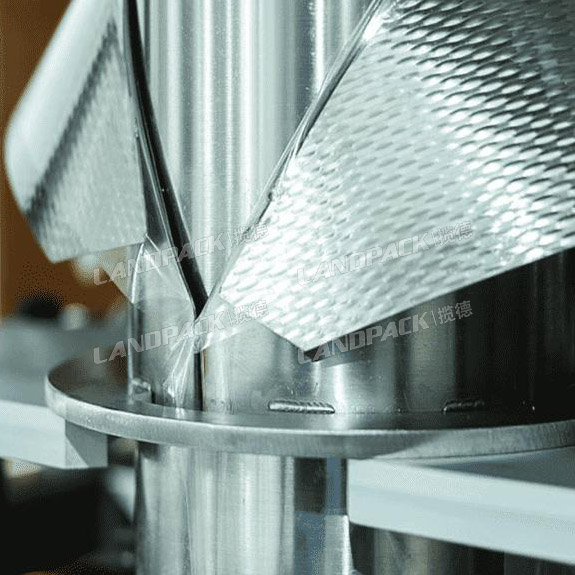

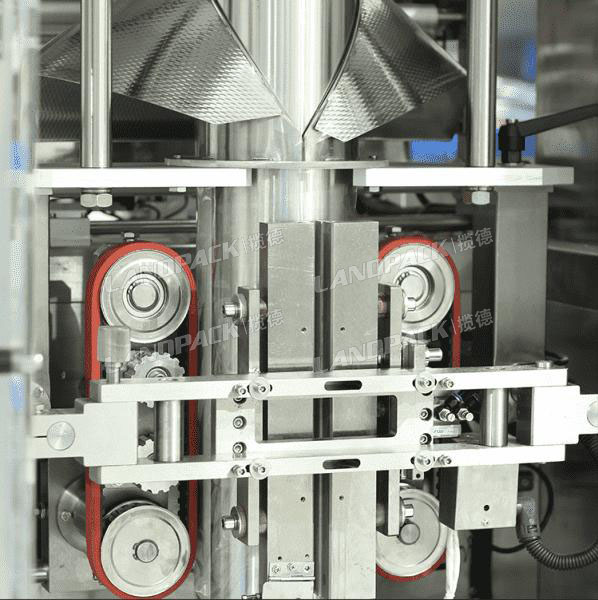

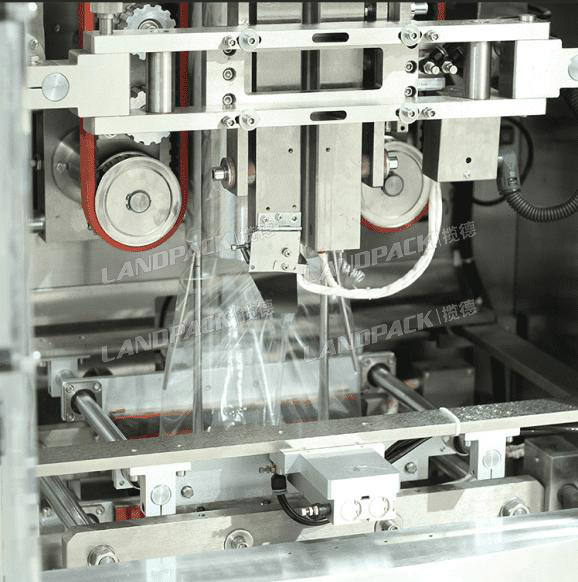

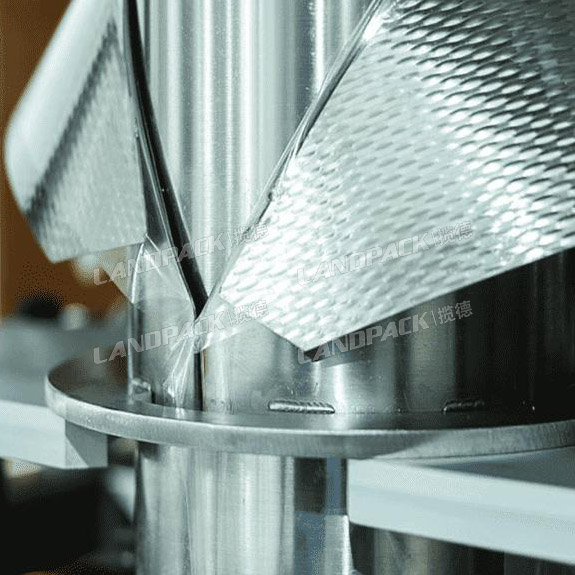

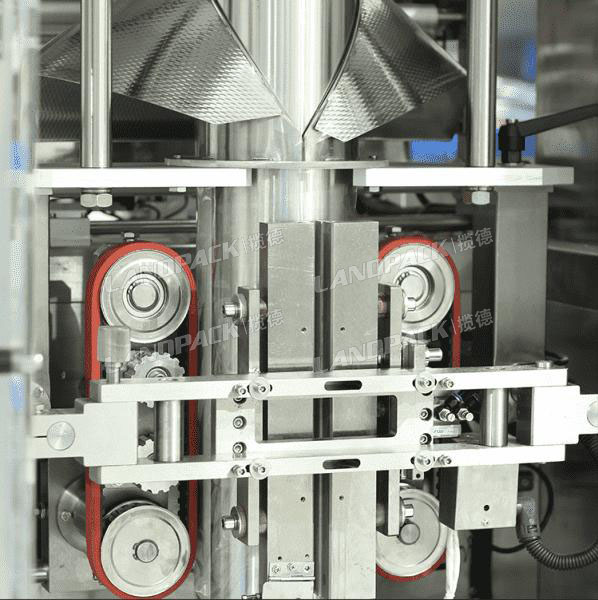

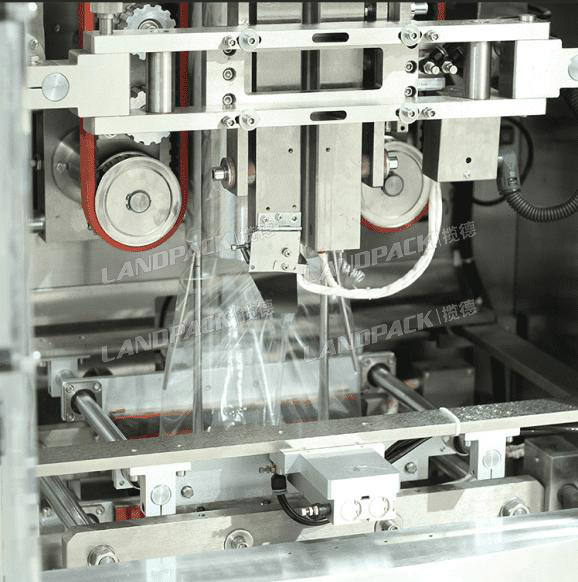

5. Bag forming

This is the bag former in the packing machine. From this device, the film will be entered into the bag former to make the bag. This is the beginning of bag-making. The film is pulled by two gear motors, which are located on both sides of the film pulling of the bag maker. If necessary, the pull-down belt of the packaging film can be held by vacuum suction instead of the friction belt. Friction belts are generally recommended for dusty products because they wear less.

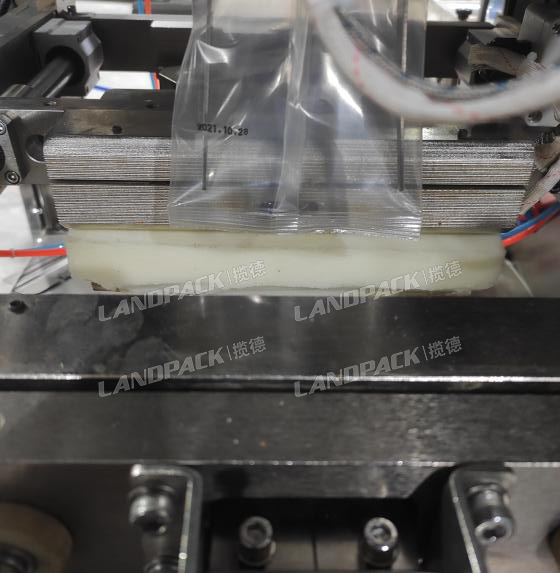

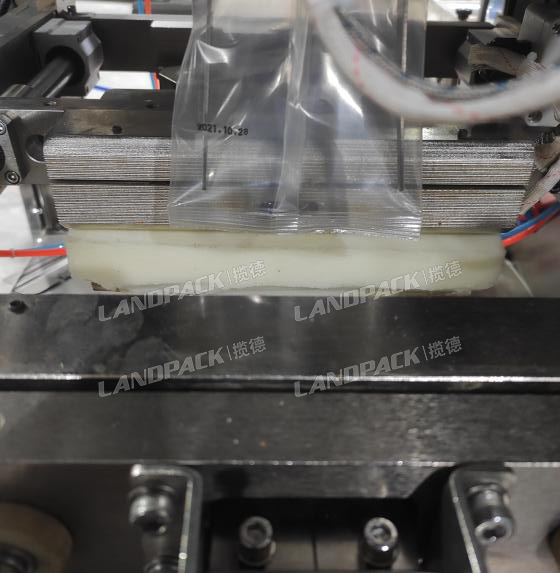

6. Bag filling and sealing

After bag making, the measured product will be dropped into the bag and then will seal the bag and cut the bag. The horizontal sealing and vertical sealing temperature can be adjusted from the control panel. They are dependent on the material of the film and bag. Heating will increase the temperature of the film, causing the film to stick to each other. The cutter cuts off the bag.

LAND PACK hopes this article can help you understand more machine work and hope that everyone can learn more machine knowledge. If you have an interest in our machine, feel free to contact us for more machine details. We could provide you the quality machines and services!