Three servo flow packaging machine

1.1、Project overview:

Pillow packaging machine is a horizontal three side sealing packaging equipment, which can automatically complete the processes of bag making, filling, sealing, cutting and finished products.

It is widely used in the assembly of automatic production lines in food, daily chemical industry, medicine and other industries.Suitable packages are generally block and cylindrical regular items, such as; Biscuits, cakes, noodles, cosmetics, paper towels, etc.

The movement curve of the transverse sealing knife of the traditional pillow packaging machine is realized by the mechanical cam, which has the advantages of complex installation, high operation noise, troublesome adjustment and low efficiency.

To solve these problems, the three servo system newly developed by our company can realize one key start, simple operation, automatic air defense, cutting and continuous material prevention in operation, and truly realize full automation.

1.2 Introduction to product advantages:

1、It can automatically calculate the material level, realize one click start after system initialization, truly zero waste, and fine tune the tangent point and feeding position during operation

2、The bag length can be set arbitrarily, from a few centimeters to a few meters. The cam function in PLC will be calculated automatically without any mechanical adjustment.

3、It has the functions of material dislocation prevention and empty slot detection

4、Electronic cams are used internally. The electronic cam has high flexibility, so the specific speed of the equipment is determined by the number of cutters, cutting length, servo rated speed and mechanical reduction ratio.

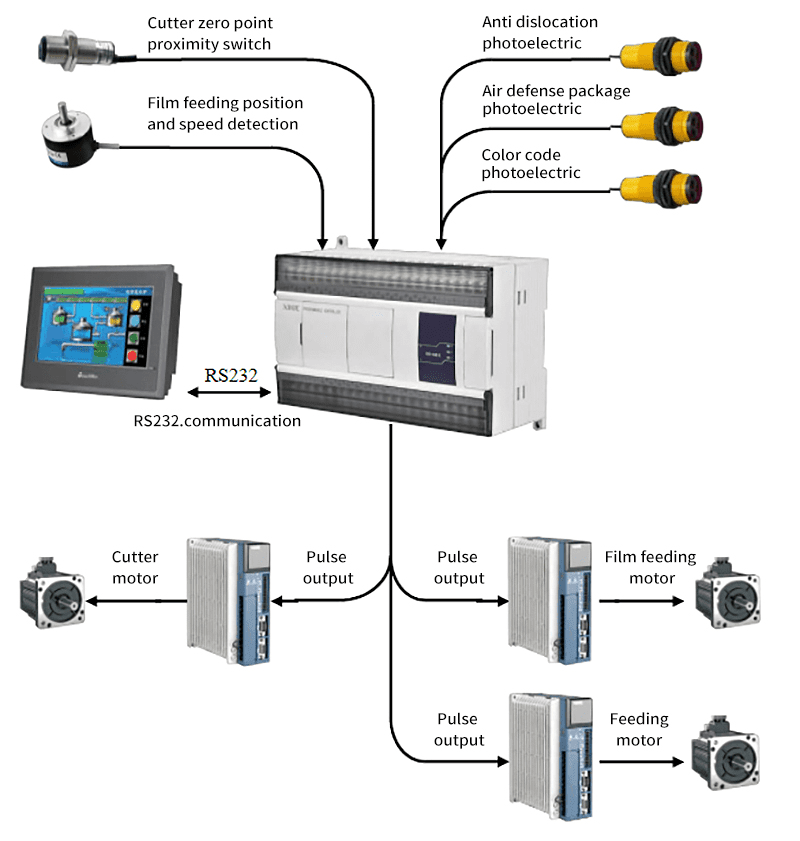

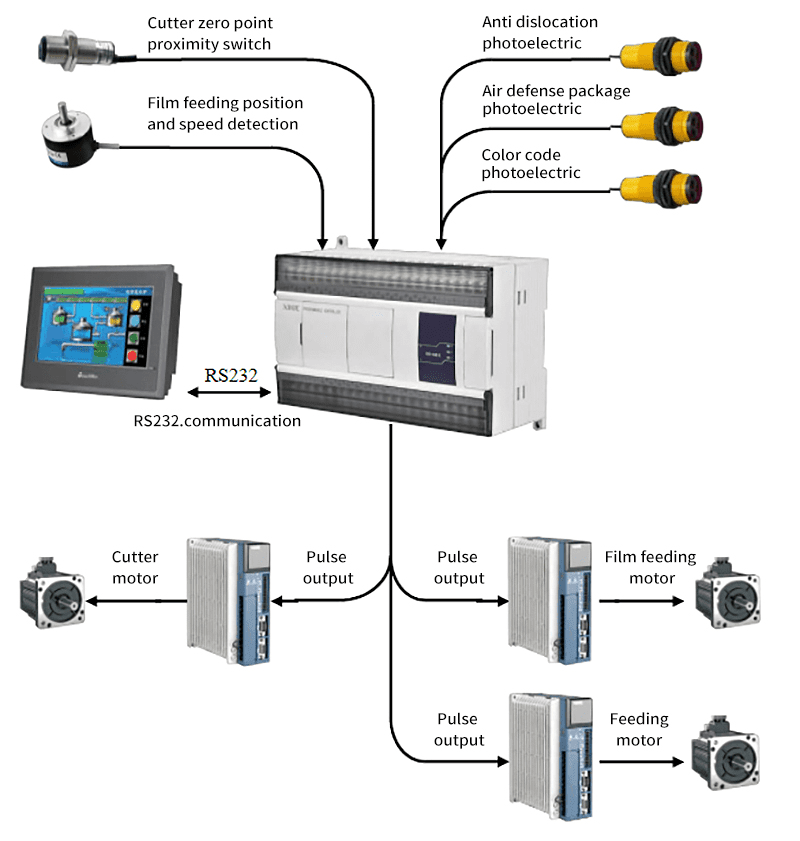

2.1 System hardware configuration:

The system hardware structure is shown in Figure .

2.2 Composition of control system:

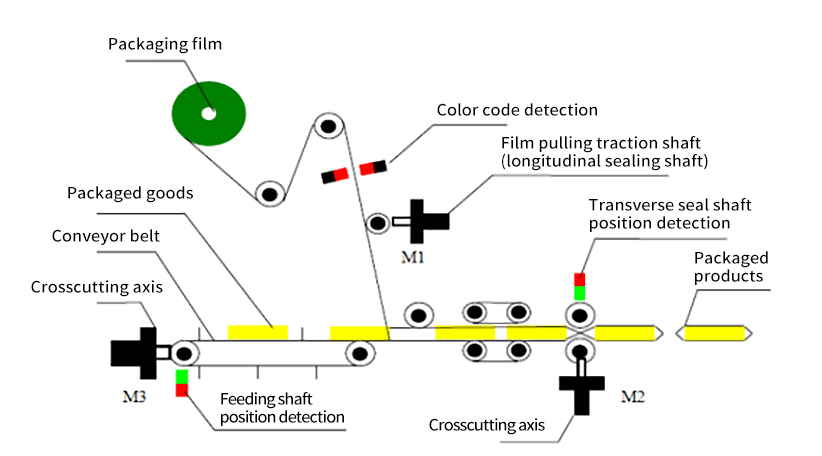

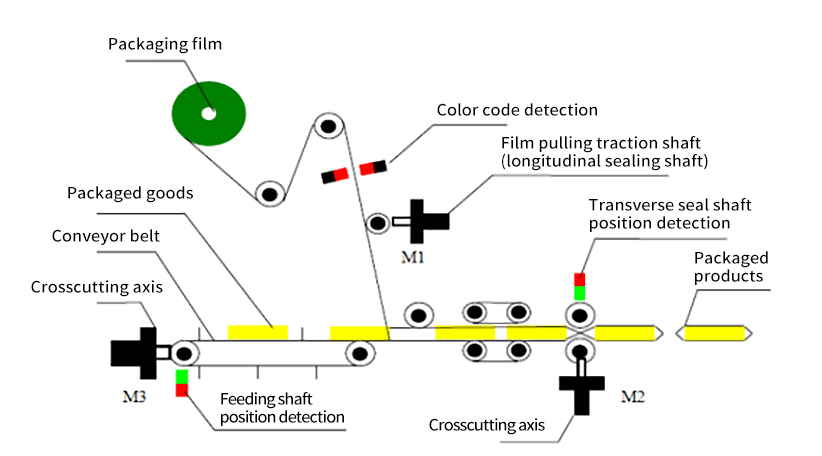

The film feeding and feeding of pillow packaging machine are carried out simultaneously. The color code detection and proximity switch detect the position of film feeding and feeding respectively. After the film is formed by the former, it becomes a cylindrical film and is subject to longitudinal heat sealing. At the same time, the materials are sent into the cylindrical film and pass through the transverse sealing and cross cutting parts together forward. The cylindrical film is sealed and cut laterally by the rotary or reciprocating transverse sealing and cross cutting knife, Output packaged products.

The process structure diagram is shown in Figure.

Shaft 1 (film feeding): the film feeding shaft is the main shaft of the system and controls the output of the film. The color code detection on the film feeding shaft is triggered when each color code signal arrives. The actual bag length is calculated through the pulse of the film feeding shaft between two triggers, so as to compensate the mechanical slip.

Shaft 2 (cutter): the cutter cuts the film longitudinally along the main shaft in the form of cam curve, and the cutting length is directly set by the touch screen. The cutter servo is set with torque limit, which can automatically judge the reason of cutting material

Shaft 3 (feeding): feeding follows the spindle in proportion. The feeding port is equipped with a photoelectric switch, which can judge whether there is material or not and whether it is continuous material, so as to control the start and pause of film feeding and cutter in front, and improve the accuracy of packaging

As can be seen from the above figure, the three axes of the transverse sealing knife shaft, film feeding shaft and feeding shaft are controlled by independent servo motors. The control requirement is that the film feeding shaft should carry the plastic film through a bag length every revolution of the transverse sealing knife shaft (assuming a single knife), and the mechanical terminal of the feeding shaft should just feed a piece of material; In this process, the three axes should be kept synchronized at all times, otherwise the packaged products may cut off the materials and the transverse sealing position may be wrong. The most important motion control requirement is that the instantaneous speed of the transverse sealing knife shaft in the sealing film must be consistent with the speed of the plastic film. If there is deviation, the plastic film will be broken or the plastic film will accumulate during the transverse sealing, resulting in unqualified packaging products.