When purchasing an automatic food packaging machine, you must first consider the customer's packaging products, including the size of the food packaging bag, packaging height, and packaging speed requirements, and determine which model to choose based on these factors.

According to the main structure and configuration components of the small food packaging machine, a high-quality automatic food packaging machine must have the following basic conditions:

1.The PLC control system selected by quality, because the control system is the core control system of the whole machine, whether the goodness of the control system directly affects the stability of the machine and the service life of the machine, therefore, the control system must be able to ensure a good brand, the industry's enterprise products, such as Taiwan imported Taiwan, Japan imported Mitsubishi, imported Siemens and other brands are worth choosing.

2.The electrical components must be selected from standard low-voltage electrical manufacturing enterprises to ensure safety, reliability and durability, because the electrical control part is the brain of the packaging machine. The composition of the control line of the whole machine must ensure the convenience of maintenance and the versatility and standardization of spare parts. It is strictly forbidden to use the old series of electrical switches and other components of the old model system that have been clearly eliminated by the Ministry of Electrical and Mechanical Services (such products reduce the cost of the manufacturer, but increase the trouble for the user).

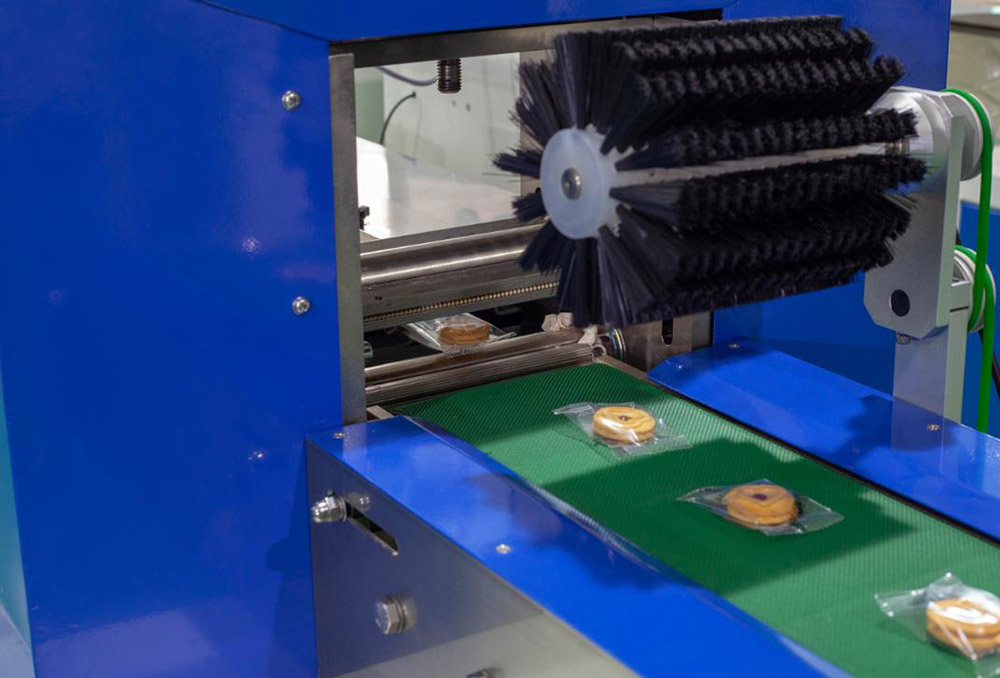

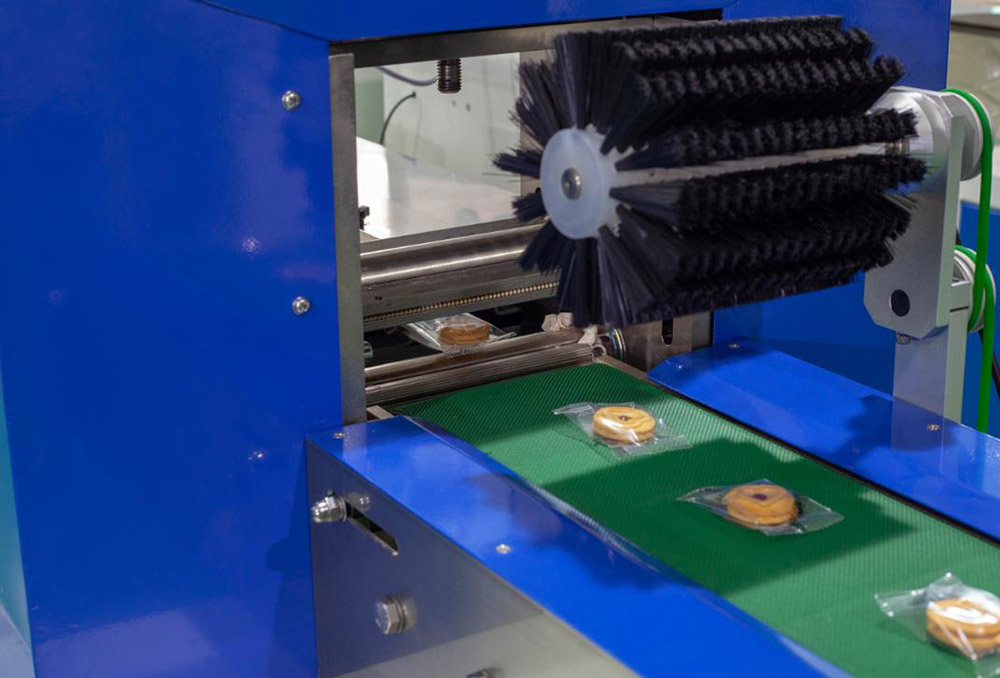

3. The steel structure of the whole machine must meet the requirements of frequent use from material to thickness, especially the structure and material use of the part in contact with the material must meet the requirements of food-grade hygiene and standard thickness and strength.

4.The appearance design of the whole machine should be reasonable, beautiful, and meet the needs of professional standardized electromechanical products, basic safety, various prompts in key positions must be complete and obvious signs, the nameplate must indicate the number of equipment, delivery delivery date, technical parameters and implementation standards.

The current standard implemented by food packaging machine manufacturers is the GB/T9177-2004 standard. The distinction of machine models is mainly determined according to the width of the sealing bag of the machine. Of course, there are many non-standard models that belong to the special requirements of users. Small bag food packaging machine, automatic food packaging machine, bagged food packaging machine, food packaging machine, automatic granule packaging machine packaging machine.